This article gives the installation recommendations that we have been providing to our customers for more than 40 years: machine and plant manufacturers, system integrators, dealers and service centers.

We have answered the most frequently asked technical questions gathering our assembly tips, guidelines and precautions that we recommend.

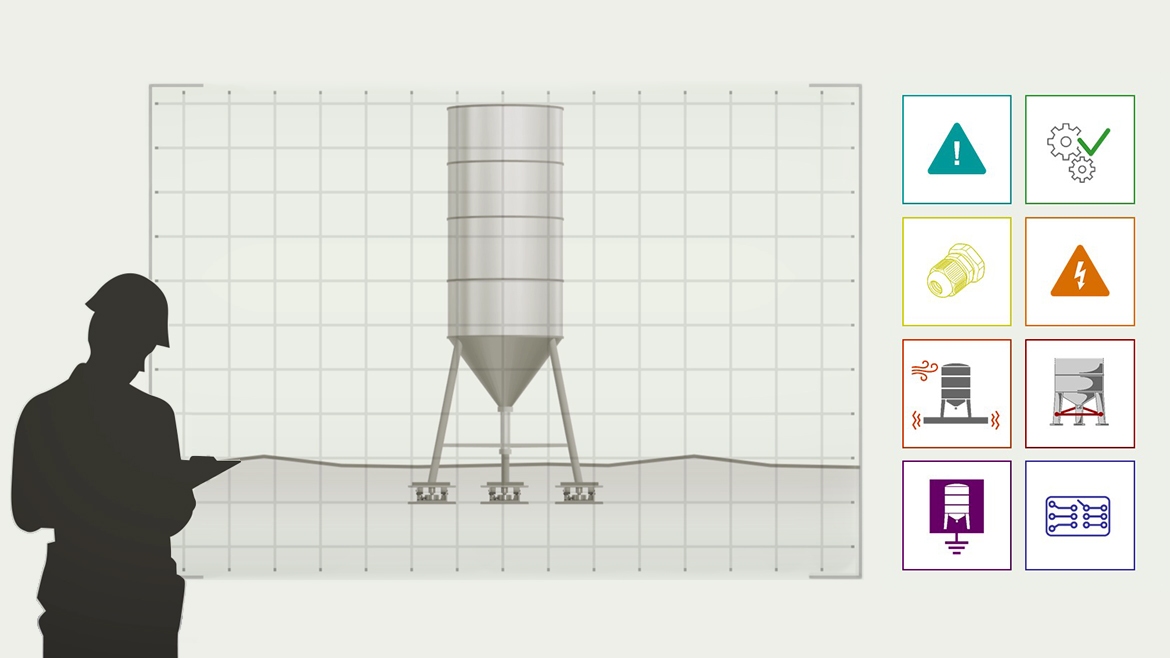

Each answer is accompanied by a short tutorial, to make it even clearer and more concrete.

1. How do you install load cells correctly?

▷ First of all, check that the support surfaces of the load cells are coplanar and perpendicular to the direction of the force of gravity.

Always use suitable mounting accessories to compensate for any slight non-parallelism between the load cell support surfaces and the base of the structure to be weighed.

The supporting surfaces must be sufficiently rigid and, if possible, non-deformable.

▷ For single-point, shear and bending beam load cells, the bearing dimension indicated on the data sheet must be respected.

▷ Pay attention to the direction of load indicated on the data sheet or on the body of the load cell by an arrow, which must point in the same direction as the applied force.

▷ To prevent the load cells from getting overloaded and therefore damaged, it is best to use the load cells at a maximum of 70-80% of their rated capacity.

This applies in the case of static weighing and with a load evenly distributed over the entire weighed structure.

Depending on how the load to be weighed is handled, consideration should be given to further reducing the load percentage in relation to the rated load capacity (e.g. when handling with forklifts, bridge cranes, etc.).

In the case of weighing with dynamic loads, the installer needs to evaluate the thrust rate, acceleration and frequency and make appropriate calculations to define the actual value of the load present and thus the correct load cell capacity.

When weighing structures with 4 supports (such as silos, tanks, hoppers, roller conveyors, belts…) take into account that the load will not be evenly distributed on them and that 85-90% of the applied load will be spread over only 3 supports.

Knowing this will help you determine the correct capacity of the load cells that you will always have to oversize in relation to the maximum load to be applied to the weighing system.

2. I need to install single-point load cells for platforms. What should I pay attention to?

Single-point and platform load cells are capable of weighing correctly within a well-defined area stated on the data sheet.

For example, if you use a load cell guaranteed for an area of 400 x 400 mm, you are certain that by applying a weight force at any point of a structure of this size, the measurement will be correct.

Whereas if you install the load cells on a structure larger than as indicated on the data sheet or if you weigh an object that protrudes from the structure, you will get an incorrect weight value and risk damaging the load cell.

3. If there are any connecting pipes in the structure to be weighed, how do I limit friction that can affect weighing accuracy?

A weighing system is all the more accurate as the weighed structure is free from friction.

When there is piping it is important to be able to avoid tension due to the connecting pipes.

How to do this?

▷ First of all, before anchoring the pipe to the weighed structure, check that this is near and in axis with the nozzle or flange to which it will be connected.

▷ Preferably use flexible hoses, bellows, elastic joints or systems with a clear opening with rubber protection.

In the case of rigid piping, it is important to have horizontal pipes.

▷ Place the first anchor bracket in the horizontal section as far from the weighed structure as possible, at least 40 times the diameter of the pipe.

▷ If, due to compelling reasons of construction, the pipe must be vertical, a soft joint or sleeve must be inserted to uncouple the assembly.

Putting these precautions into practice will help you reduce friction and increase the accuracy of the weighing system.

4. How do I check if a load cell has been installed correctly in a weighing system?

To verify the correct mechanical installation of the weighing system, the weight indicator must be set to zero and a force applied to the system and then removed.

The indicator must return perfectly to zero.

In the case of a weighing system with multiple load cells, repeat this step at each load cell.

With the system loaded, the weight values should be similar on each load cell; with the system unloaded, they should indicate zero.

5. How to connect multiple load cells in parallel? What characteristics should the extension cables used for the connection have?

To connect multiple load cells in parallel, use a watertight junction box, with a suitable terminal block, or a multichannel transmitter in the box.

▷ For cables into and out of the box or multichannel transmitter you will need to install cable glands.

▷ To protect the load cell cables use sheaths and watertight fittings.

▷ The extension cables used for the connection must be shielded.

▷ We recommend using a 6-wire cable with reference/sense management, which can compensate for the voltage drop due to the distance between the devices.

If possible, the cable should be inserted into the conduit on its own and routed as far away from the power cables as possible.

If you are using connection cables with 4 conductors, make sure that they have a minimum cross-section of 1 square millimeter and that they do not exceed 300 meters in length.

Finally, avoid using load cells with cables of different lengths.